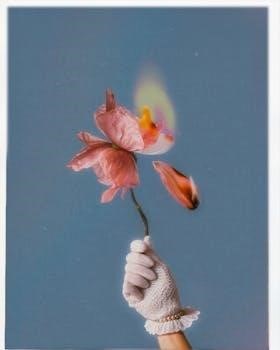

The burning test is a straightforward method for preliminary fiber identification. It involves observing how a fiber reacts to flame, noting its burning behavior, odor, and residue. This simple test is a practical first step in fabric analysis.

What is a Fiber Burning Test?

A fiber burning test is a basic technique used to identify different types of textile fibers by observing their behavior when exposed to an open flame. This method involves igniting a small sample of the fiber and noting characteristics like flame color, odor, how the fiber burns, whether it melts, and the nature of the residue or ash left behind. It’s a quick, accessible, and preliminary way to categorize fibers.

Why Perform a Fiber Burning Test?

Performing a fiber burning test helps in preliminary identification of unknown fabrics. This simple test aids in determining the basic fiber type, whether natural, synthetic, or blended, based on its combustion characteristics.

Importance of Fiber Identification

Identifying fiber content is crucial for various reasons. It enables informed decisions about fabric care, appropriate usage, and printing suitability. Accurate fiber knowledge aids in communication with suppliers, ensures correct pricing, and prevents reliance on misleading labels. Understanding fiber properties is vital for garment design and performance. It is very important in preventing the suppliers from taking advantage of the lack of experience and knowledge.

Pricing and Supplier Communication

Knowing the exact fiber content is essential for accurate fabric pricing. If sourcing from dead stock or unknown sources, fiber identification is needed to estimate costs. This knowledge empowers informed communication with suppliers, ensuring transparency and fair dealings. It also prevents suppliers from taking advantage due to a lack of fiber knowledge and is helpful when negotiating prices and understanding the true value of materials.

Materials for Conducting a Burning Test

Essential materials include a heat-resistant dish, tweezers, a lighter or matches, and small fabric samples. A water source should be nearby for safety. These basic tools allow for controlled testing.

Essential Supplies

For conducting a fiber burning test, gather a heat-resistant container like a ceramic plate or metal can, avoiding plastic. You’ll need tweezers to hold the fabric snippets, a lighter or matches for ignition, and a water source for safety. Small scissors are useful for cutting the fabric samples. Having these supplies ensures a safe and effective testing process, allowing for accurate observation of burning characteristics.

Sample Preparation

To prepare a sample for the burning test, carefully cut a small, triangular snippet from the fabric, about one inch in length. It’s crucial to use only fiber or yarn, not the whole fabric swatch, to avoid misleading results due to blended materials. This small, manageable piece will allow for focused observation of the burning characteristics without interference from other fibers or fabric finishes.

How to Perform a Fiber Burning Test

The burning test involves carefully exposing a fiber sample to a flame, noting its behavior, odor, and any residue. Observation of these characteristics will help in fiber identification.

Step-by-step guide

First, cut a small, triangular snippet of the fabric. Then, using tweezers, hold the snippet over a fireproof dish. Ignite the fabric with a match or lighter, allowing it to catch fire. Carefully observe how the fiber burns. Note whether it melts, shrinks, or continues to burn after the flame is removed. Observe the color of the flame, the odor produced, and the characteristics of any ash or residue left behind.

Observation Criteria

When performing the burn test, pay close attention to several key aspects. Note whether the fiber melts or burns. Observe if it shrinks away from the flame. Document the odor produced during burning; is it like burning paper, hair, or chemicals? Examine the flame’s color and whether smoke is produced. Finally, analyze the ash residue, noting its color, shape, and texture, as these details help in fiber identification.

Burning Characteristics of Natural Fibers

Natural fibers, derived from plants and animals, exhibit distinct burning behaviors. These differences in flame, odor, and ash are crucial for their identification using the burning test method.

Animal Fibers (Wool, Silk)

Animal fibers, such as wool and silk, are protein-based and tend to burn slowly, often with a smell similar to burning hair. They typically form brittle, crushable beads when burned and continue to burn after the flame is removed, but not for long. The ash is typically dark and easily pulverized. These fibers react uniquely to flame.

Cellulose Fibers (Cotton, Linen, Viscose)

Cellulose fibers, including cotton, linen, and viscose, exhibit a rapid burning behavior with a calm, yellow flame. They produce white smoke and continue to burn even after the flame is removed, leaving behind a minimal amount of light grey ash, resembling paper ash. The burning process releases an odor similar to burning paper, aiding in their identification.

Burning Characteristics of Synthetic Fibers

Synthetic fibers often melt or shrink away from the flame. They tend to produce black smoke and chemical-like odors. The residue is usually hard, black beads or ash.

Polyester

Polyester shrinks quickly when exposed to a flame, and it burns slowly while melting. The smoke produced is typically black, and it emits a chemical, plastic-like odor. After removing the flame, it does not continue to burn. The residue left behind is often in the form of hard, round, black beads. This behavior is key to identifying polyester in a burn test.

Nylon

Nylon also demonstrates rapid shrinking when introduced to a flame. It burns and melts slowly, often forming small bubbles during the process. The smoke is black, and a chemical, celery-like odor is noticeable. Similar to polyester, nylon will not continue to burn once the flame is removed. The residue typically forms hard, round, black beads, which is a telltale sign.

Acrylic

Acrylic fibers react to flame by shrinking quickly. The burning flame tends to sputter, and black smoke is produced during combustion. Unlike some other synthetics, acrylic will continue to burn even after the flame source is removed. The resulting ash is typically yellow-brown in color, has a regular shape, and is hard to the touch.

Identifying Blended Fabrics

Blended fabrics, composed of multiple fiber types, present a challenge. Their burning behavior combines characteristics of each fiber. Careful observation of the ash and odor can help identify the blend’s components.

Mixed Fiber Behavior

When burning blended fabrics, the fibers’ individual burning behaviors combine, making identification more complex. For example, a cotton-polyester blend may exhibit both the paper-like burning of cotton and the melting of polyester. Observing the burning rate, smoke, and the residue’s characteristics carefully will help identify components of the blend. The resulting ash will often present a mix of characteristics from each fiber.

Examples of Blends

Common blends include cotton-polyester, which combines the comfort of cotton with the durability of polyester. Another example is wool-nylon, often used for socks to add strength. Rayon-linen blends offer a mix of drape and breathability. These blends exhibit varied burning behaviors, making them more challenging to identify than pure fabrics. Careful observation of the resulting ash and odors is essential to distinguish them.

Interpreting the Results

Analyzing the ash, odor, and flame color provides critical clues. Ash can be powdery, beady, or crusty, with varying colors. Odors may be like burning paper, hair, or chemicals. These details help identify fiber types.

Analyzing Ash Characteristics

The residue left after burning, known as ash, is a key indicator in fiber identification. Observe the ash’s appearance closely. Is it powdery and easily crushed, or does it form hard, bead-like structures? Note its color, which can range from light grey to dark black, and its shape, whether regular or irregular. These details help narrow down the fiber type.

Odor and Flame Color

The scent emitted during burning is a critical factor in fiber identification. Does it smell like burning hair, paper, or a chemical? Note the color of the flame, as it can vary from yellow to orange or even blue. A calm, yellow flame suggests natural fibers, while a sputtering flame with black smoke often indicates synthetics. These observations complement the ash analysis.

Advantages and Limitations of the Burning Test

The burning test is a quick, accessible, preliminary method for categorizing fibers. However, it is not definitive for precise identification, especially with blended fabrics or treated materials.

Preliminary Test

The burning test serves as an initial screening method, offering a quick way to categorize textile fibers. It helps differentiate between natural, synthetic, and blended materials by observing their burning behavior. This test provides valuable insights for further analysis but is not definitive for precise fiber identification. It’s a simple, accessible way to gain preliminary information about a fabric’s composition before more complex methods.

Not definitive identification

While the burning test is a useful preliminary tool, it’s important to recognize its limitations. It cannot provide exact identification of specific fibers. Factors like fiber blends and finishes can influence the burning characteristics, leading to potential misinterpretations. Therefore, results from a burning test should be considered as indicative rather than conclusive. Further testing may be required for precise fiber identification.

Safety Precautions

When conducting a fiber burning test, ensure a fire-safe environment. Use a non-flammable surface, have water nearby, and properly dispose of any residue to prevent accidents.

Fire Safety

Always perform the burning test in a well-ventilated area, away from flammable materials. Use a fire-resistant surface like a ceramic plate or metal can, and keep water or a fire extinguisher nearby. Never leave the flame unattended, and exercise caution when handling burning fibers. Ensure that all participants are aware of the safety protocols, and have a first aid kit accessible. Proper fire safety is key for safe testing.

Proper Disposal

After completing the burning test, allow all ashes and residues to cool completely before handling them. Dispose of the cooled remnants in a non-flammable container or ashtray. Do not discard hot or smoldering materials in the trash, as this could lead to a fire hazard. Be responsible and follow local guidelines for safe disposal of laboratory waste. Make sure everything is completely extinguished.